A wide range of shapes and bends from the Columbus archives, new and old.

Columbus have developed super-light tube sets for the greatest champions: Coppi, Anquetil, Baldini, Rivière, Bracke, Ritter, Merckx, Moser, Oersted. Intelligent experimentation and technological progress continues to be the focus of the Columbus.

Hyperion:

• Columbus' cold-drawing technology improves the mechanical properties of

• Hyperion tubes compared to other Titanium tubes available on the market,

with a +22% increase in UTS relative to non-butted tubes.

• Columbus' special proprietary drawing-lubricant provides extra-clean tubes out

“of the box”, without residual oils. This allows builders to prepare tubes for

welding more quickly.

• Main triangle and rear stays in Grade 9 Ti: optimal for performance and

workability.

• Headtube and bottom bracket in Grade 5 Ti: maximum rigidity in the most

stressed zones of the frame.

• Thanks to Columbus ability to produce titanium headtubes from tubes rather

than solid billets, we are able to oer a single model suitable for all frame sizes.

• Columbus is a 360° framebuilder partner for all your tubing and component

requirements across dierent materials.

• Access to Columbus' historical archive of tube shapes including a wide range of

bent rear stays and an exclusive range of shaped downtubes.

XCR: Stainless, seamless, performance

• The jewel of the crown, top-range tubeset

• The only biphasic stainless seamless tube family

available in the cycling industry

• Tripled & Double butted tube reinforces

• High corrosion resistance in long-term periods in

every use and weather condition

• Seamless-technology, improved stiff ness and mechanical properties

• Reduced thickness, up to 0.4mm for an extremely

reduced weight

• Exceptional resistance to Stress Corrosion Cracking

• No need to be painted or clear-coated after polishing

• Ultra smooth surface (Ra<0,4)

• Excellent weldability

• Made in Italy

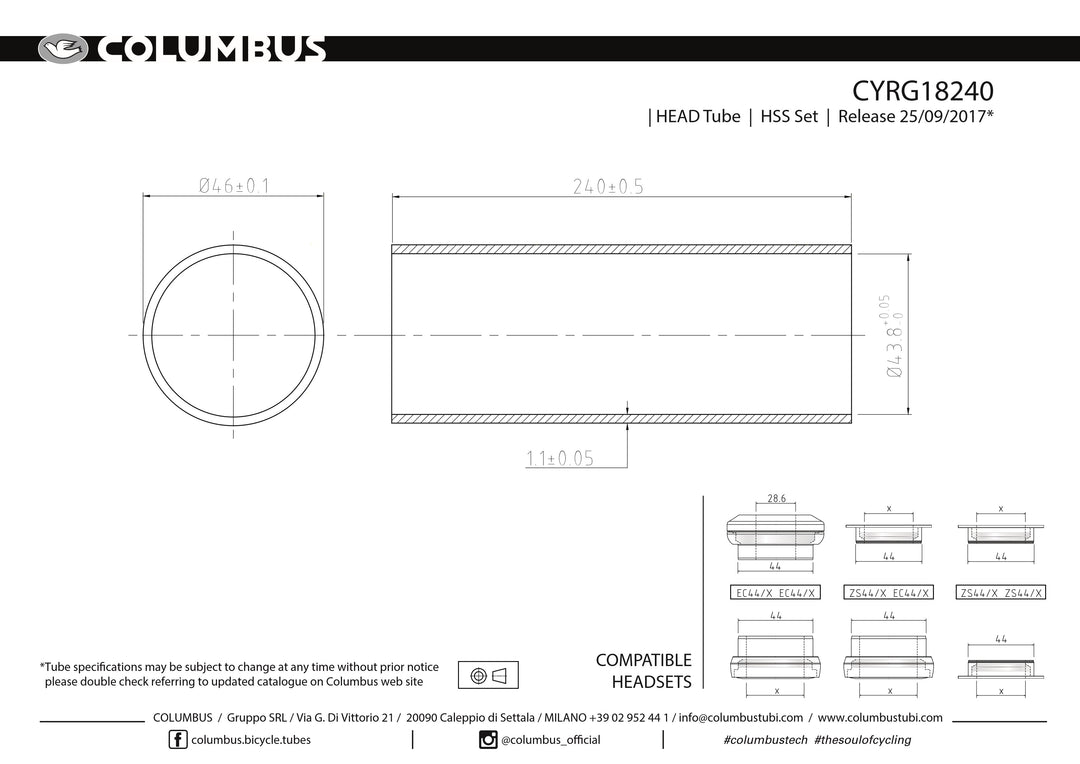

SPIRIT HSS: High-strength shaped

• Triple butted OMNICROM alloy

• Cold-Drawn Seamless Tube

• Exceptional mechanical properties

• Special HSS shaping, designed to

optimize tube strength according to the orientation

of its local solicitations

• High tensile strength, superior resilience and

incredible fatigue resistance

• Visual Quality Control inspection and hand marking

of each tube

• Unpaired strength/weight ratio

• Made in Italy

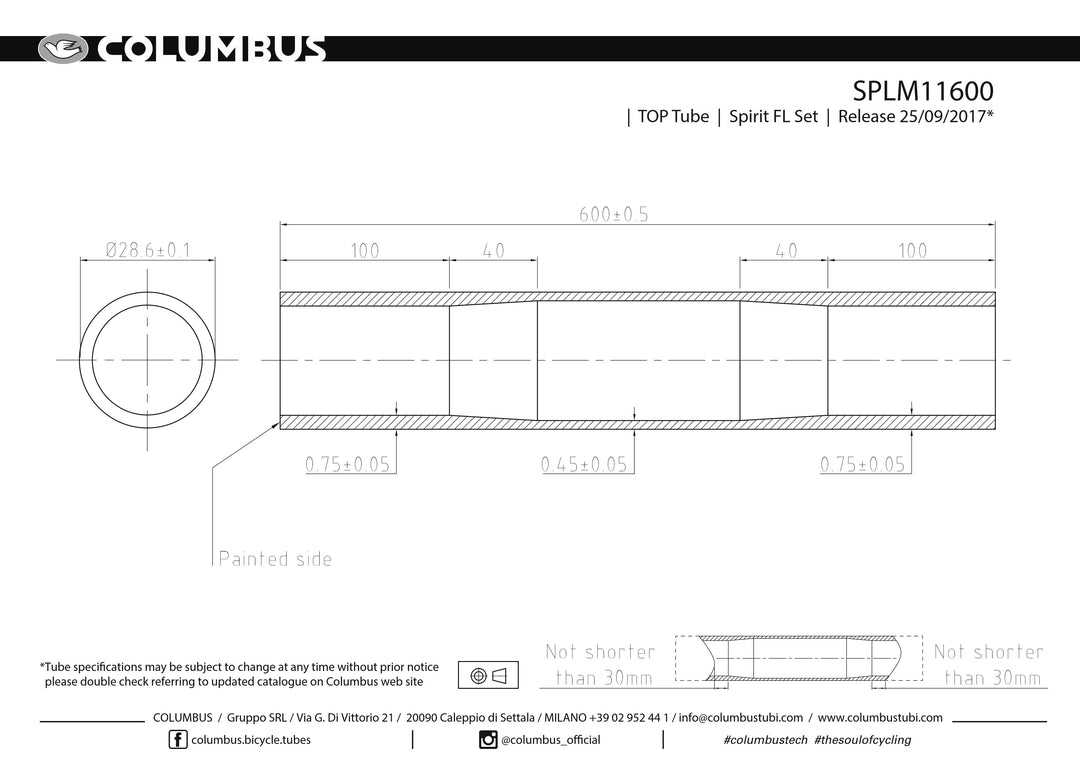

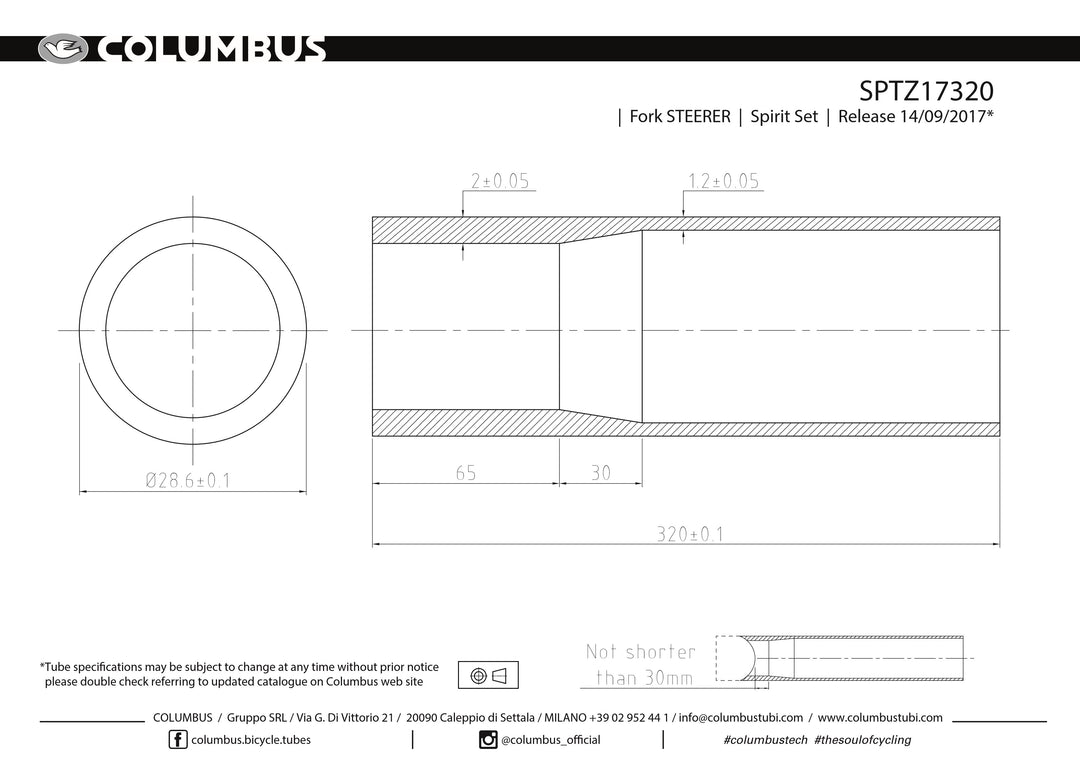

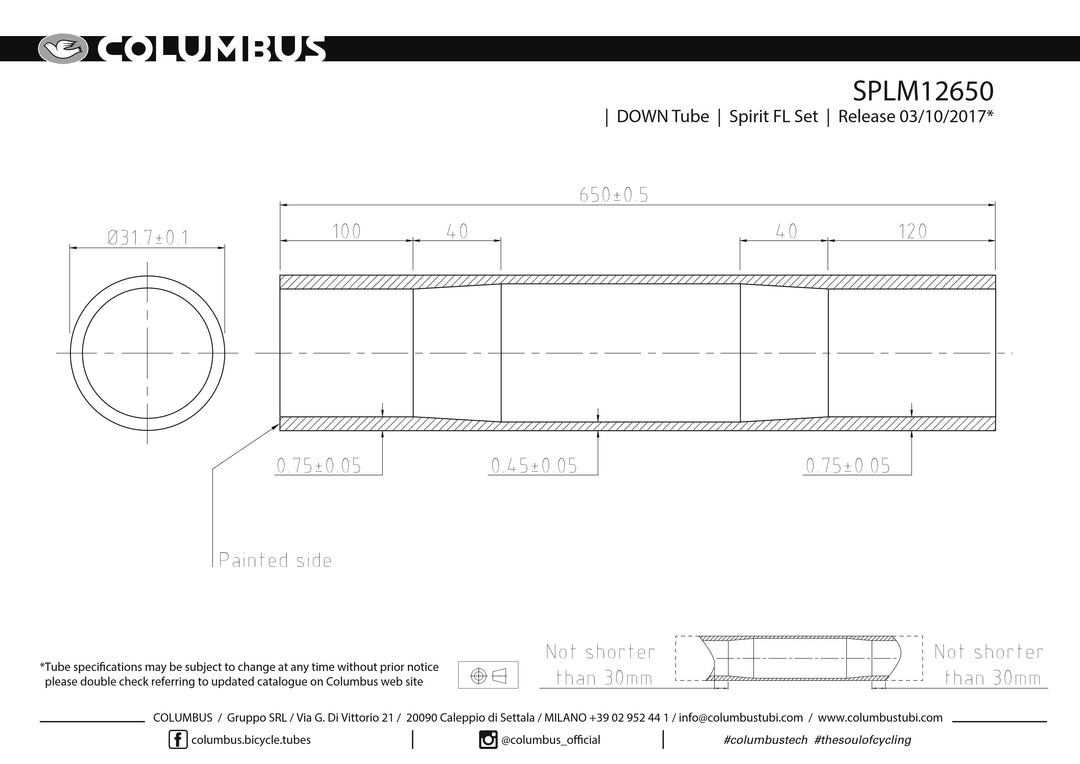

SPIRIT: Top-performance road-race

• Triple butted OMNICROM alloy

• Cold-Drawn Seamless Tube

• Reduced thickness, up to 0.38mm

• Exceptional mechanical characteristics

• High tensile strenght, superior resilence and

incredible fatigue resistance

• Excellent tube-surface finishing and highly controlled alloy-composition,

regular and close to nominal, for an excellent weld

bead

• Visual Quality Control inspection and marking of

each tube

• Incomparable strength/weight ratio

• Made in Italy

LIFE: Oversize, lightness, resistance

• Triple butted OMNICROM alloy

• Cold-Drawn Seamless Tube

• Wide range and great freedom in

frame-design & tubeset-composition

• Excellent resistance/weight ratio, wide range of

shapes & bends

• Over-sized tubes available for the DT (Ø42mm) and

the ST (Ø35mm)

• Exceptional mechanical characteristics

• High breaking load, superior tenacity and

incredible fatigue endurance

• Wide range of specifi cations: road-race, gravel,

urban and mtb

• Made in Italy

MAX: The revolutionary tubeset

• Triple butted OMNICROM alloy

• Cold-Drawn Seamless Tube

• The very fi rst and only original patented

non-round tubeset of the cycling history

• Tubes shapes oriented according to localized

specifi c stress-direction

• Elliptical and oriented oversized sections for an

increased momentum of inertia

• Maximized stiff ness, reduced thickness, weight and

power-dispersion

• Made in Italy

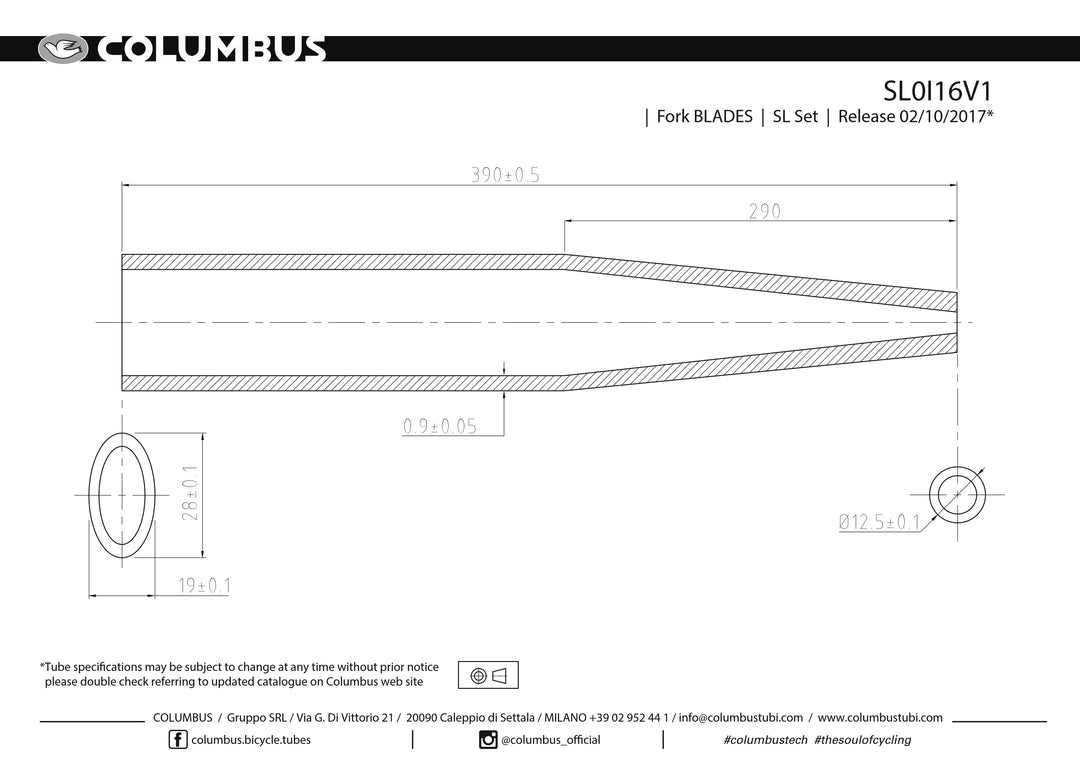

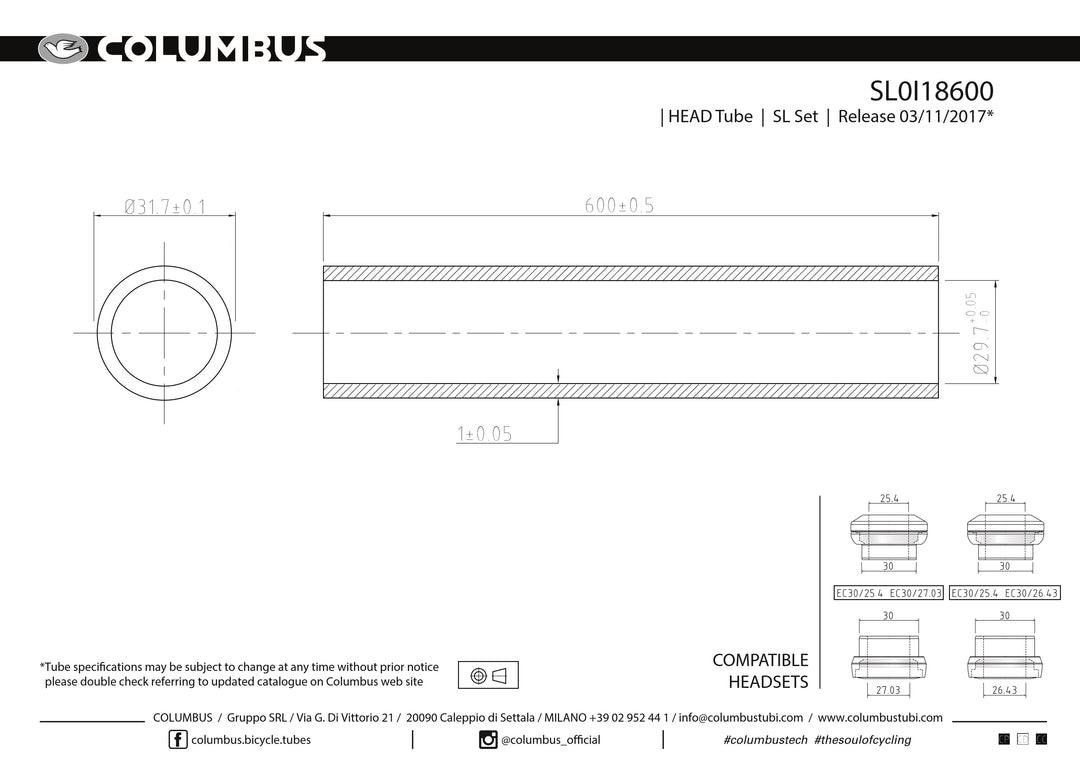

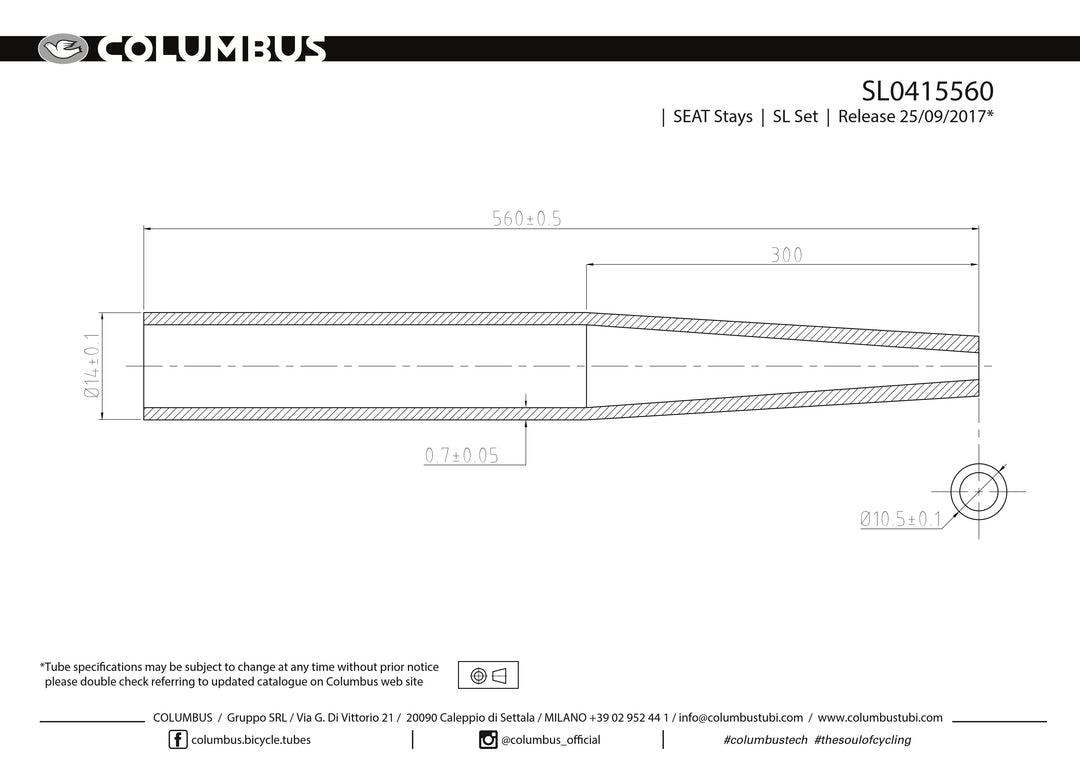

SL: Super Leggera - The ‘Soul of Cycling’

• Double butted OMNICROM alloy

• The most famous Columbus round set

• Hi-performance, imperial dimensions

• Exclusive laminated tapered fork blades

swaged on shaped-mandrels for an improved

structure and lightness

• Wide range with multiple diameters and thicknesses and reinforces

• Meets both lugged and Tig-welded frame needs

• Evergreen specifi cations updated to new technologies and alloys

• Double butted seamless tubes, cold worked and stress relieved

• Made in Italy

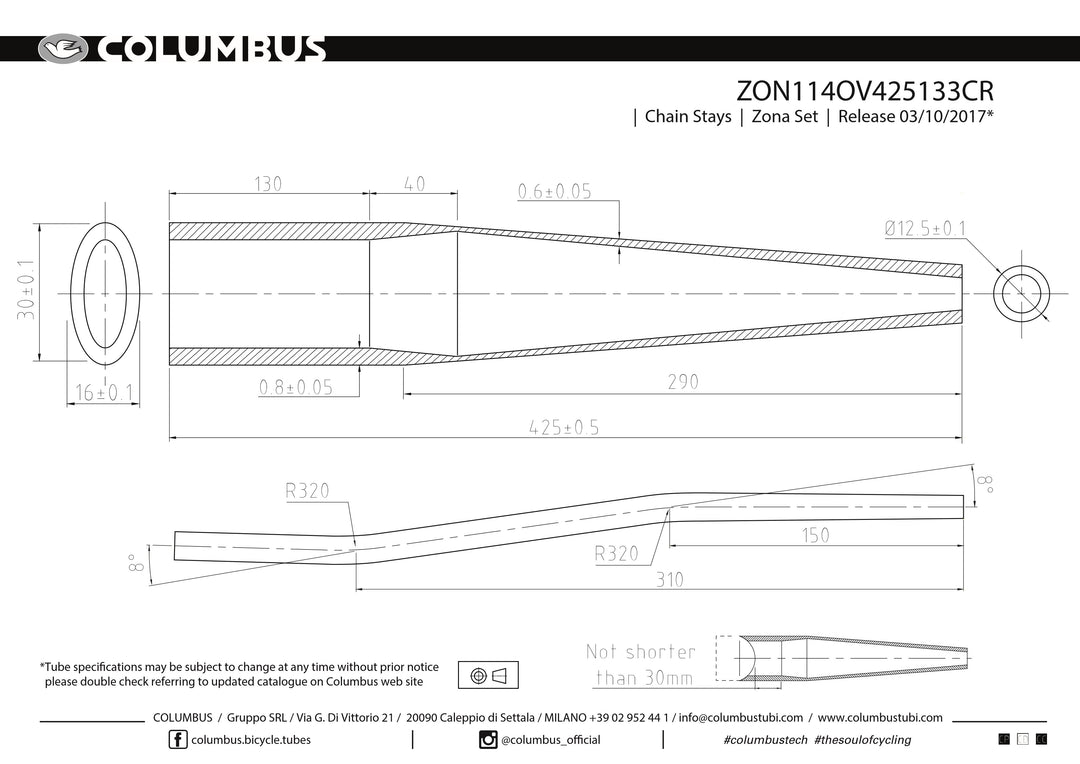

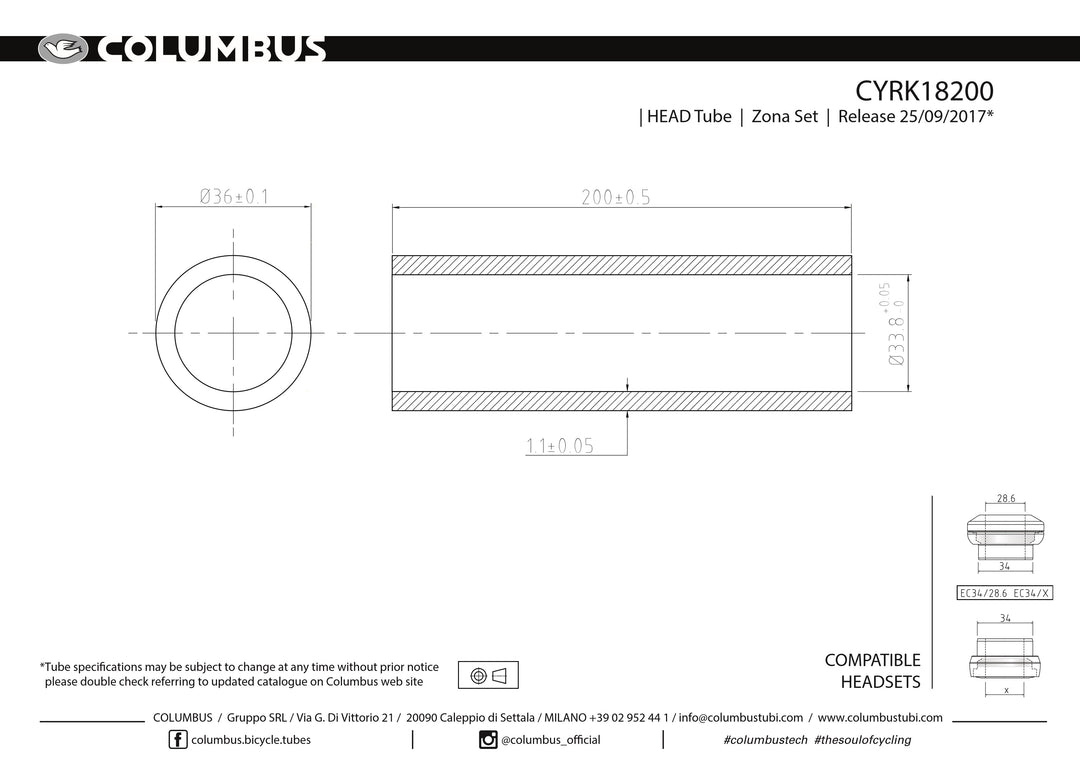

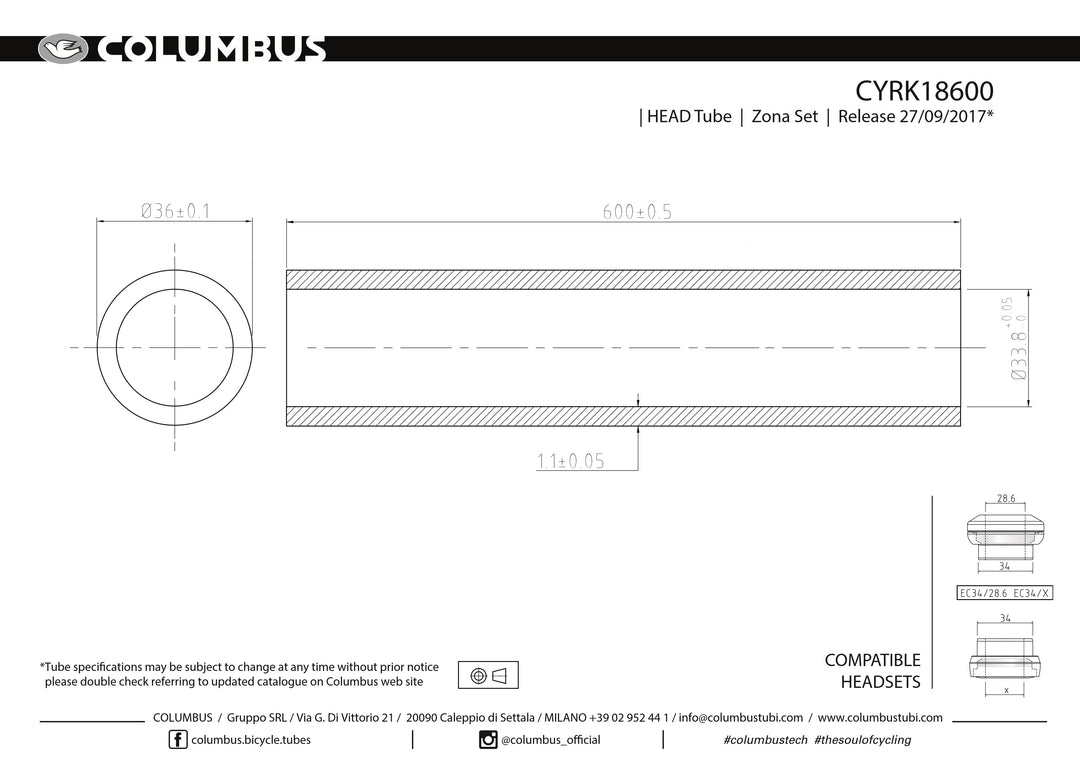

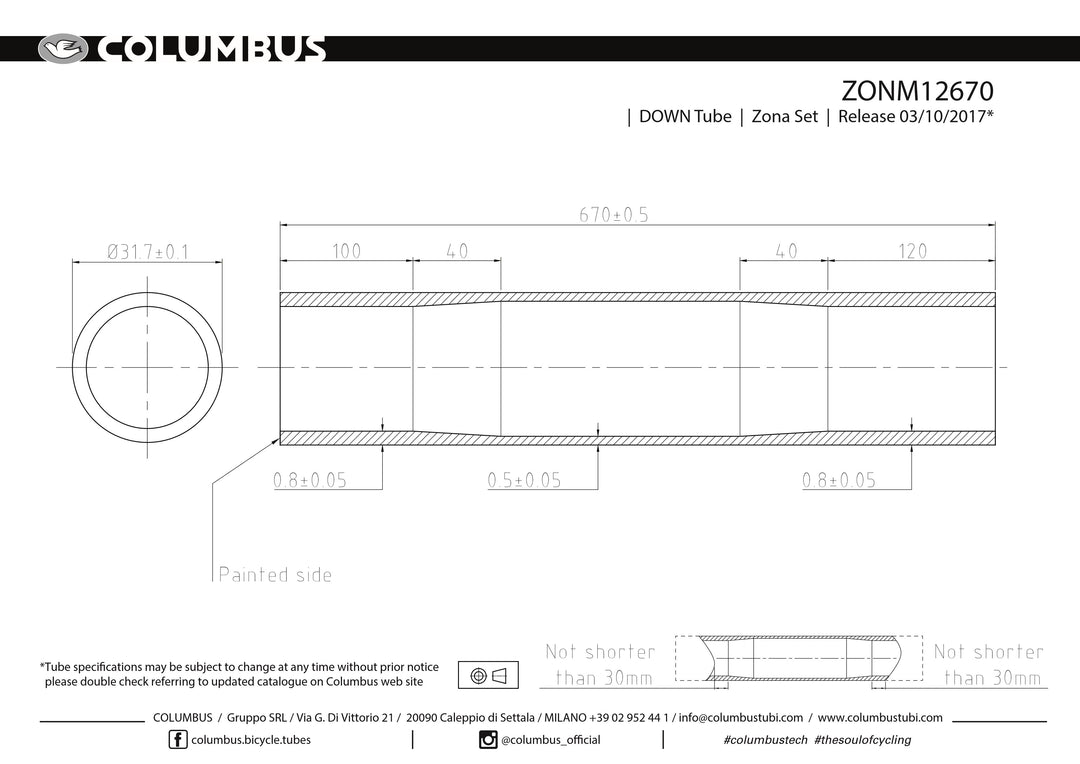

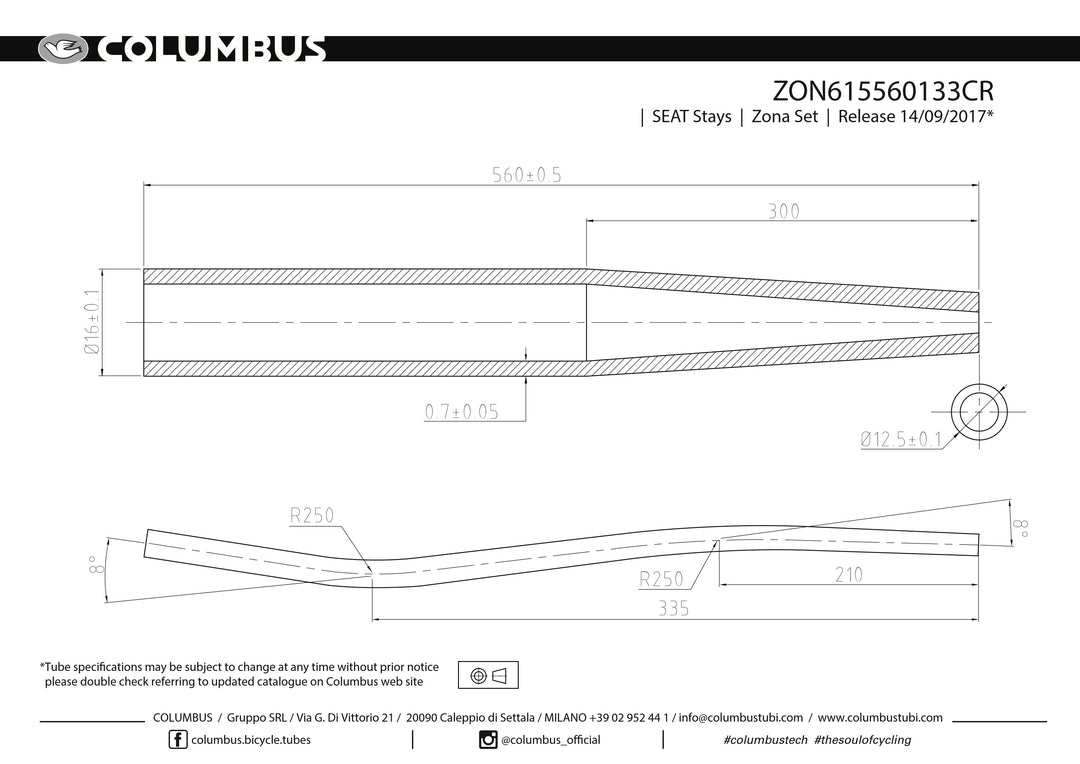

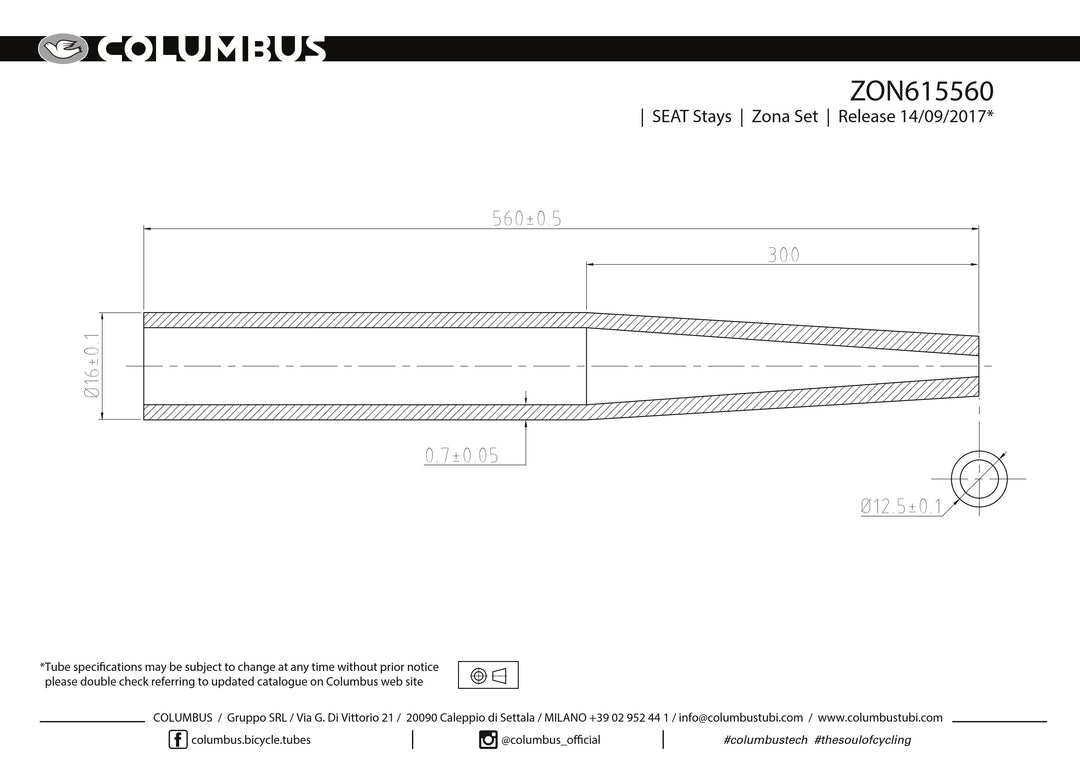

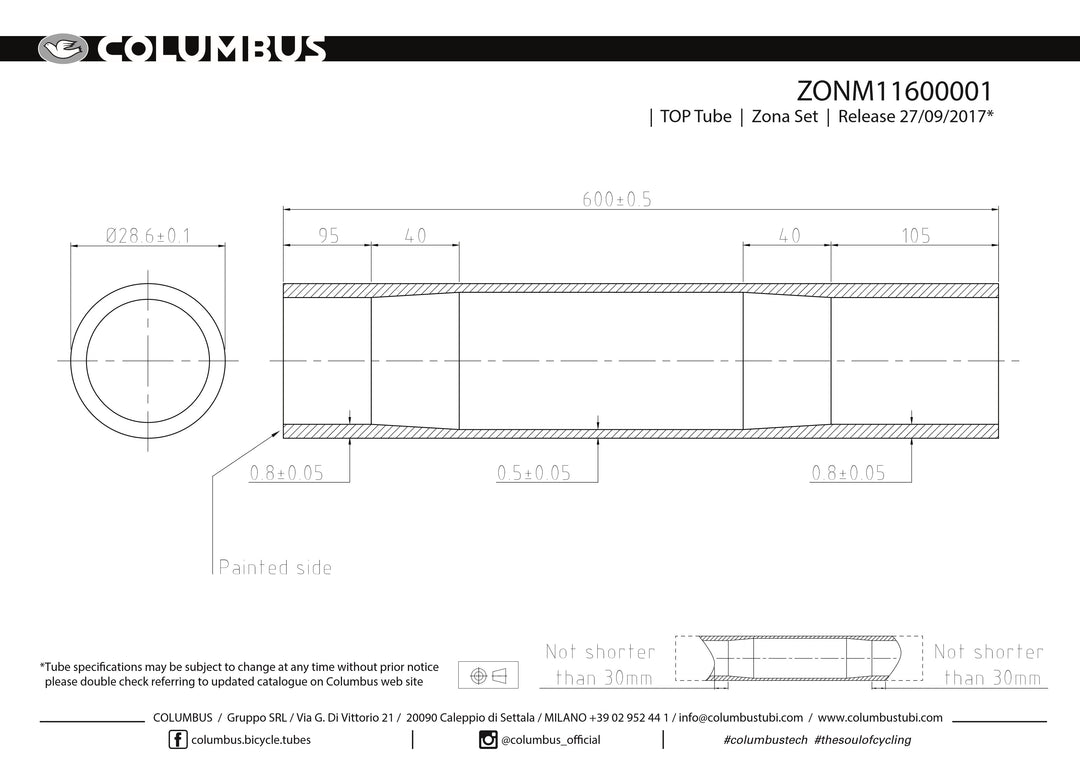

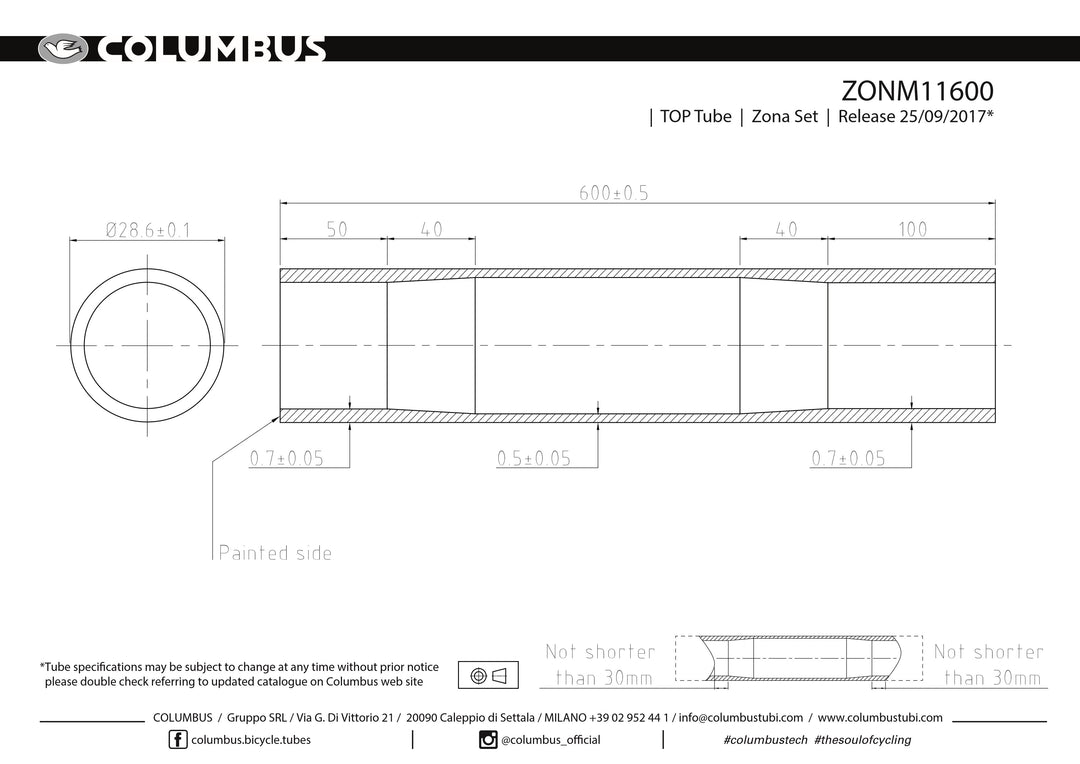

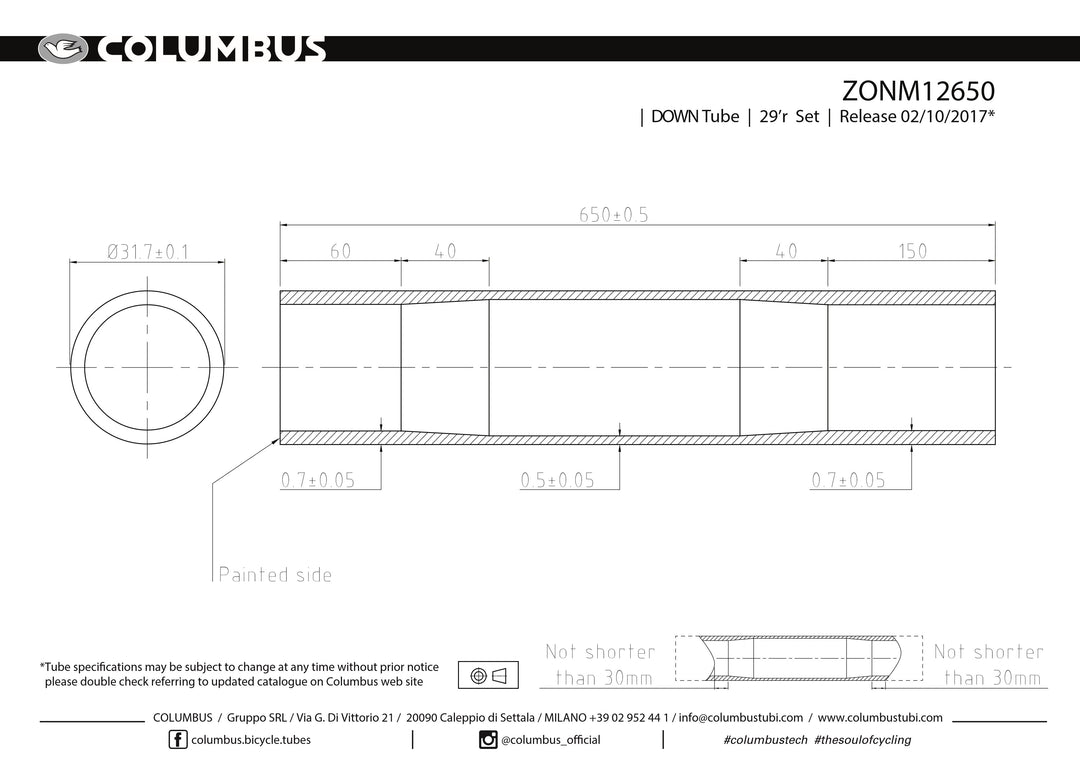

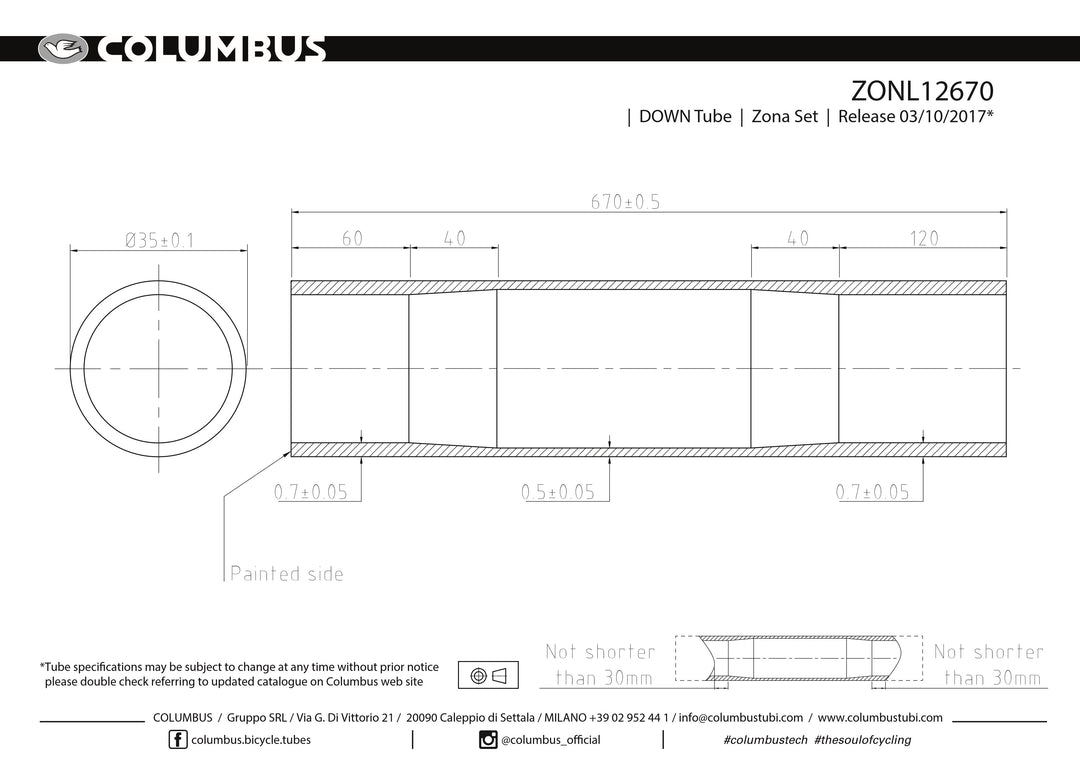

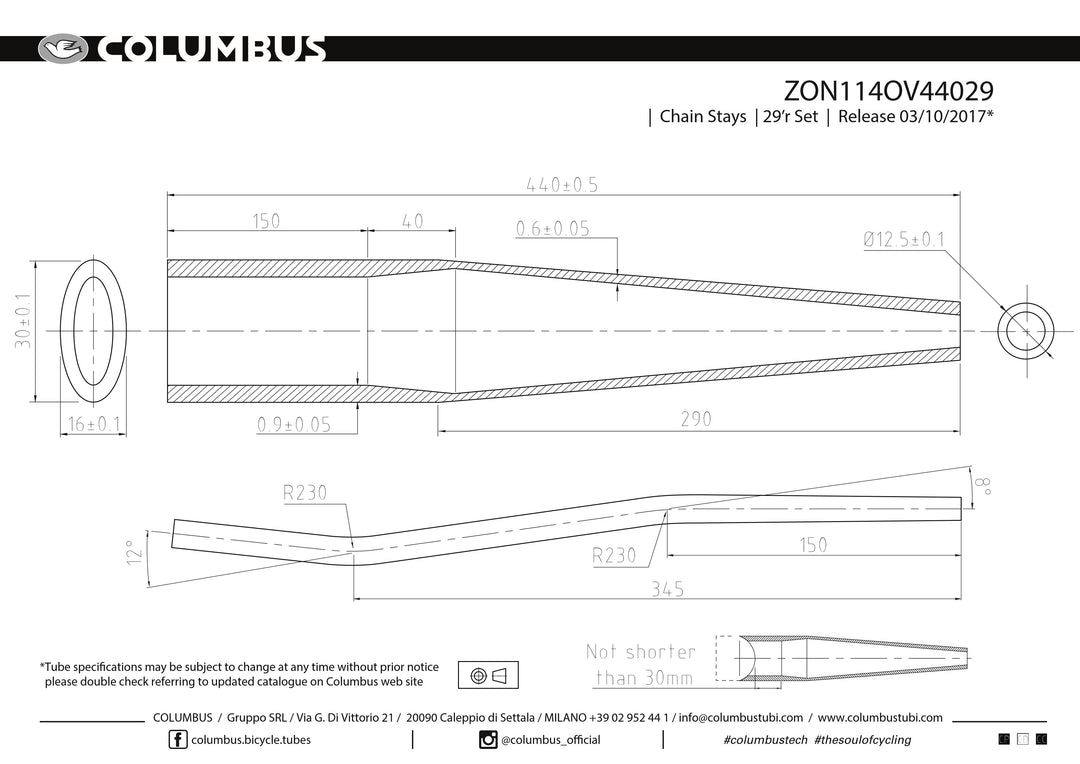

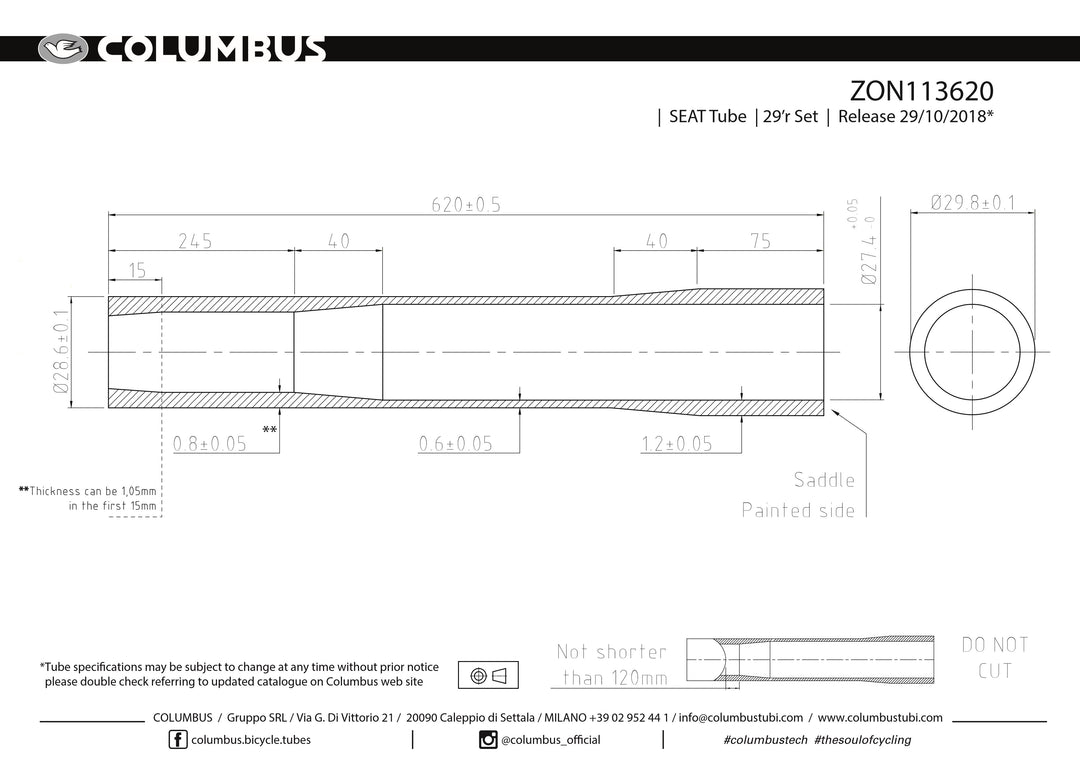

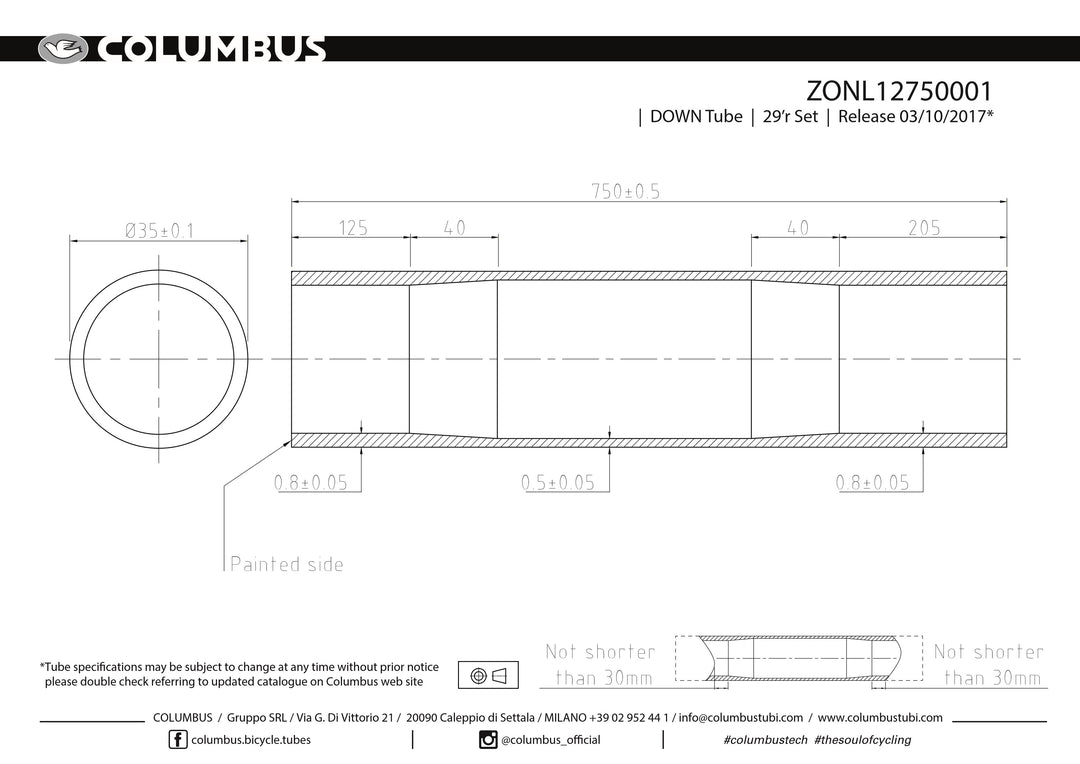

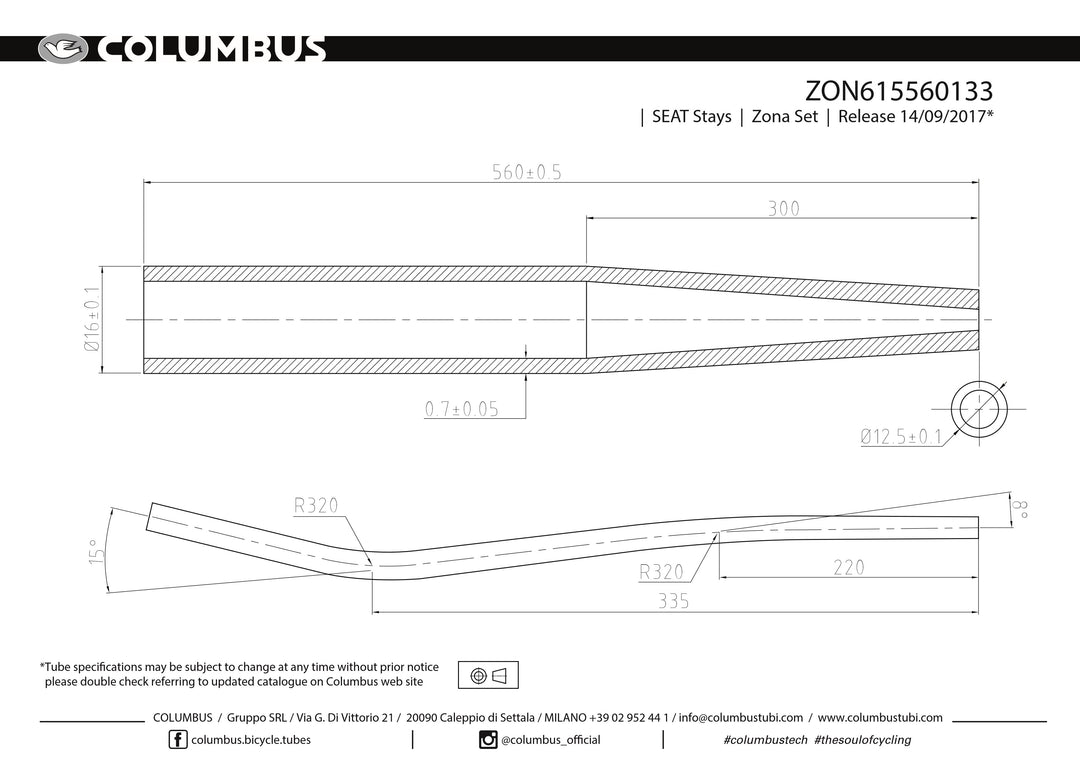

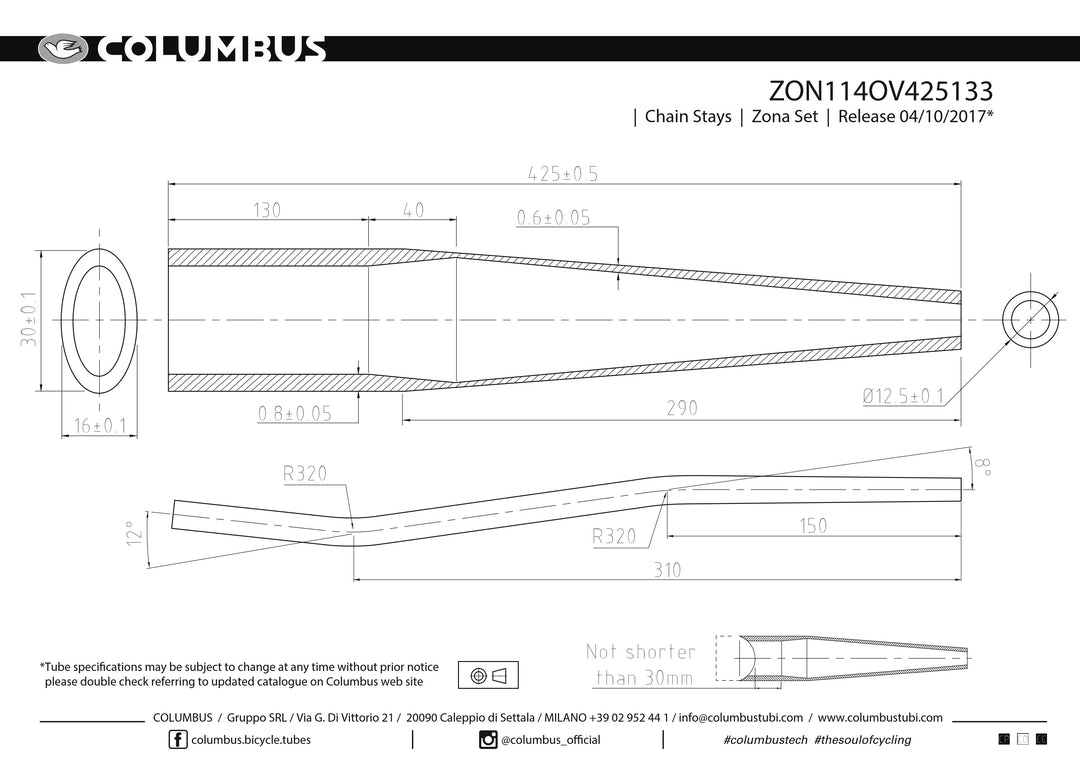

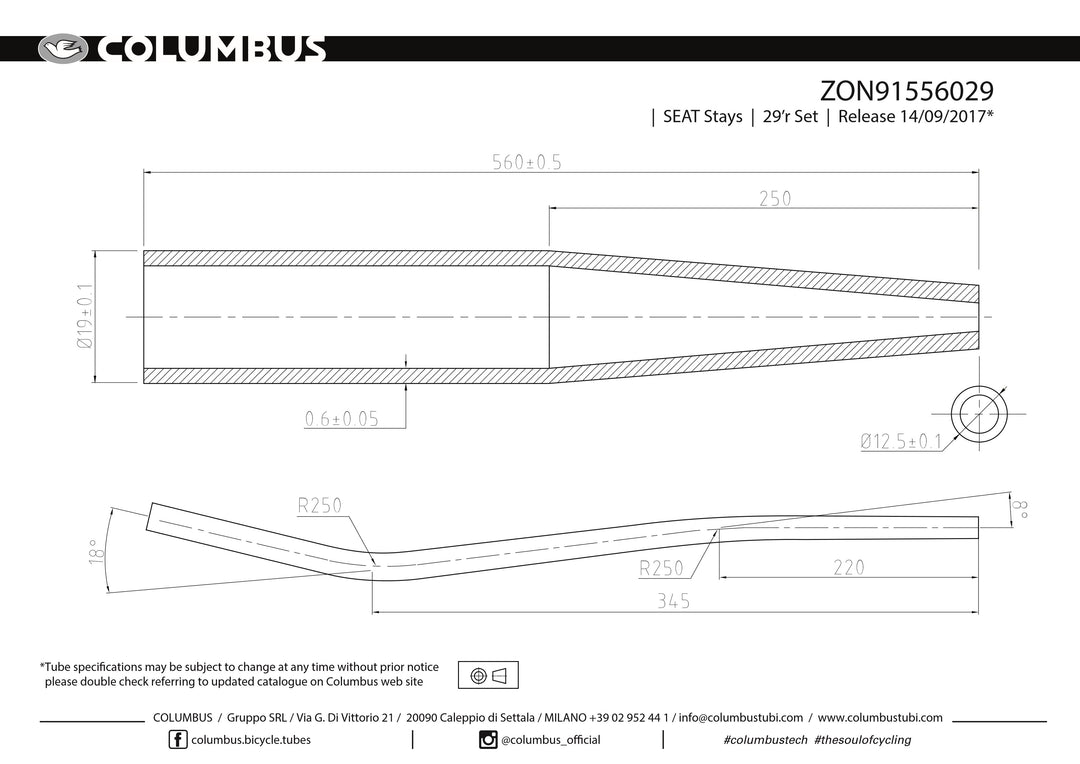

ZONA: All-purpose, high-resistance tubes family

• Triple / Double butted 25CroMo4

alloy seamless tubeset

• Moderate weight and high strenght

• Multiple possible shapes, triangle & stays

• Increased wall-thicknesses and butted lenghts in

strategic tube areas

• Perfect solution for off road and training purpose

• Great to mix with lighter Columbus sets for an

improved resistance

• Good resistance to heating during welding process

• Great reliability and fatigue life

• Made in Italy

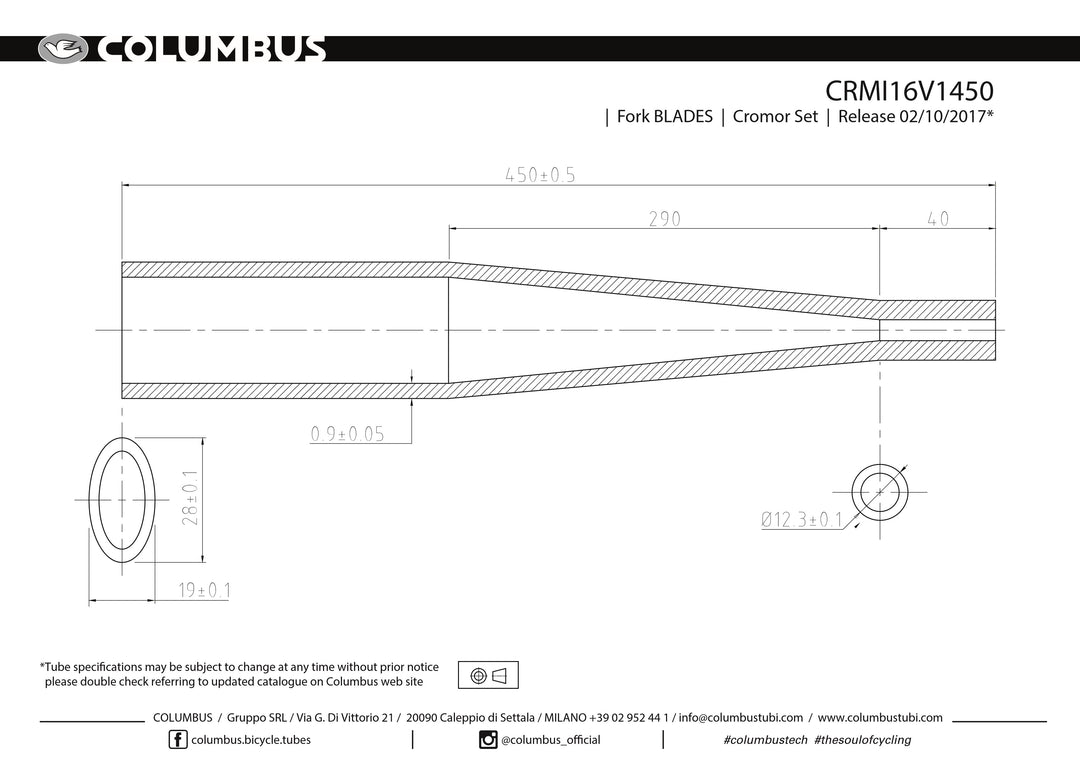

CROMOR: Resistance, reliability, duration

• Double & Single butted Cromor alloy

• Competitive and easy to weld & braze

• The legendary Columbus tubeset

• The ABC of framebuilding art

• Reinforced in the welding/junctions areas up to

0.8/0.9/1.2mm

• Tubes with reduced thickness up to 0.5/0.6mm

• Top reliability even in the most demanding and

stressing conditions

• Long-lasting properties and performance even

after heavy-duty use

• Improved performances with multiple cold-drawn

& stress-relief processes

• Full-set made in Italy. ‘Tre-Tubi’ composition

available ex-Asia for OE ..productions